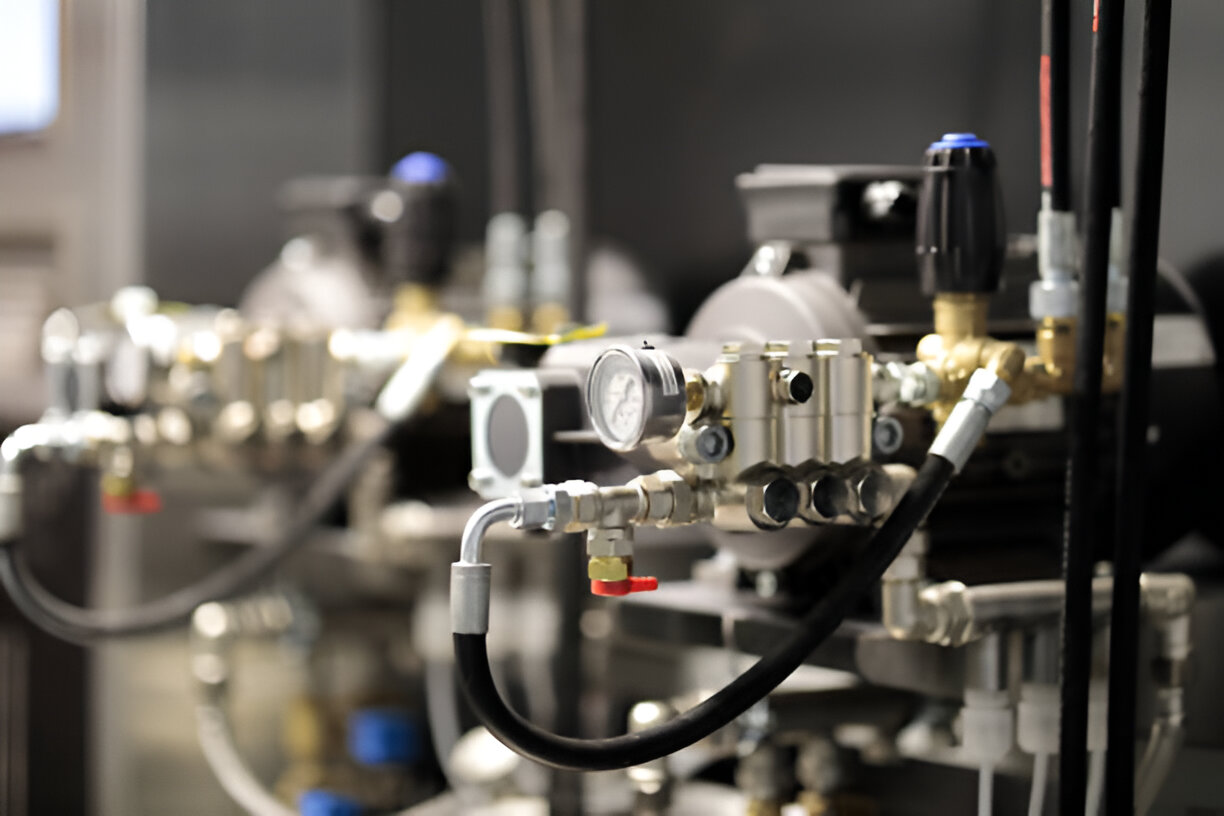

The Model XYZ-2020 main engine, designed for long-haul maritime vessels, relies on a series of hydraulic components to enhance its performance and ensure operational reliability. Below is an in-depth look at essential hydraulic system components in this engine:

1. Hydraulic Pumps

Hydraulic pumps are critical for generating the pressure needed to power various hydraulic systems within the engine. In the XYZ-2020, high-efficiency hydraulic pumps ensure a continuous flow of hydraulic fluid, which is essential for operating mechanisms like pistons, valves, and cylinders. These pumps are designed to maintain stable performance even under high-stress, long-duration operations. The efficient design minimizes energy loss and maximizes hydraulic pressure to various parts of the engine.

2. Cylinder Pistons

Cylinder pistons play a key role in converting hydraulic pressure into mechanical movement. In the XYZ-2020, these pistons are designed for heavy-duty applications, ensuring smooth operation under extreme conditions. The hydraulic cylinders in the engine’s system use these pistons to carry out functions such as lifting, pressing, and powering other mechanical components within the engine.

3. Pressure Valves

Pressure valves are essential for regulating the hydraulic system’s pressure, ensuring that it does not exceed safe operational limits. In the XYZ-2020, these valves are calibrated for precision to prevent damage to sensitive components and ensure the engine operates within safe parameters. They work in conjunction with hydraulic pumps and cylinders to maintain a consistent pressure level throughout the system, optimizing the engine’s performance.

4. Hoses

High-strength hydraulic hoses are used to transfer fluid between the different components of the hydraulic system. In the XYZ-2020 engine, these hoses are made from durable materials that can withstand high pressure, temperature variations, and exposure to corrosive elements, making them suitable for harsh marine environments. Properly installed hoses ensure that hydraulic fluid flows smoothly without leaks or pressure loss, contributing to the overall efficiency of the engine.

5. Control Valves

Control valves are responsible for directing the flow of hydraulic fluid to various parts of the system based on operator inputs. In the XYZ-2020, these valves allow precise control over the engine’s hydraulic operations, enabling operators to adjust parameters such as speed, load, and power distribution. The valves are designed for quick, responsive adjustments to ensure smooth, efficient operation in dynamic maritime conditions.

Conclusion

The Model XYZ-2020 main engine’s hydraulic system is a vital part of its overall performance, relying on components like hydraulic pumps, cylinder pistons, pressure valves, hoses, and control valves. Each of these parts contributes to the engine’s ability to function reliably under demanding conditions, ensuring efficient operation, minimal downtime, and optimal performance during long voyages. By ensuring that hydraulic pressure is properly managed and fluid flows efficiently, the hydraulic system plays a crucial role in powering the main engine and keeping the vessel operational.